Engineering Services

BAeHAL is a proven industry leader in offering high-quality engineering services.

We run business outcomes for OEMs - Aerospace and Defence organizations.

WHO WE ARE

We, the team of engineers, who believe in exploring and catering to the indented best technology

Our services and solutions help the Organization to reach the zenith

OUR VALUE

Providing extensive engineering solutions and give the right insights to the customer.

Striving for customer delight through our deliverables on time and every time.

OVERVIEW

We offer end-to-end engineering solutions across aerospace product development and product lifecycle management. We build trust with our customers which helps to accelerate product development and innovation cycles.

With our expertise in cutting edge technology, we provide solutions in the area of CAD/CAE, Aerospace Design, Mechanical Design, Model-Based Definition, Flight Test Activities, and Casting Simulation.

Aerospace

BAeHAL offers a wide range of IT, design and manufacturing solutions to meet the nation’s aerospace requirements for commercial & military applications.

Defence

We deliver state-of-the-art technological and manufacturing solutions to help the nation’s military adapt to the evolving demands of warfare.

Automotive

Our engagement with one of the major Automotive OEM’s, our solutions includes Legacy data conversion on floor panel, bonnet, doors, waist rail, step well, created master geometry surface from manual drafts for rooftop, front panel, interior panels.

Combat Aircraft and Rotary Wing

BAeHAL Engineering Services has been a driving force in the development of Combat Aircraft and Rotary Wing. Our solutions improve operational capabilities and reduce design cost. We are supporting in Design, Development, and Analysis of Combat Aircraft from nose to tail. Value added by designing both primary and secondary structure in composites and metallic. Services and solutions in Kinematics simulation, Digital Mock up, Design of piping, tubing, Tooling Design, Design of Jigs, fixtures, Electrical and Avionics Systems. Also carried out flight test activities which includes Aircraft test Flight Snags, Flight Test Data Analysis, Data Maintenance and Validation

Commercial Aircraft

Over a decade BAeHAL is providing solutions and ideas not only in defense but also in commercial aircraft for their renowned OEMs and their Tier one/two companies. We have been providing Design assessment and Stress assessment such as static & fatigue analysis for study of discrepancy observed during manufacturing. BAeHAL has wide range of experience in High End Digitization & Digital Mock-up of single Aisle & Twin Aisle Transport Aircraft.

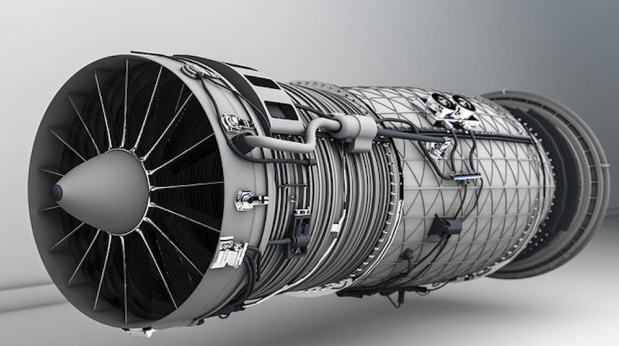

Aero Engines

With a total number of 3000+ parts and 500+ assemblies, our team is powering the Indian defence with KAVERI Engines. We have dedicated Engineers who are working for the betterment of the Engines and have faced a lot of challenges, covering key areas such as Fan, Compressor, Combustor, Turbine, Exhaust, Jet pipe with CD nozzle, Gear Box, Bypass Duct, Lubrication & Rotor Sub Systems.

Armaments & Ammunition

The engineering team at BAeHAL is committed to optimizing industrial readiness for government-owned Dhanush which is a 155 mm towed howitzer used by the Indian Army. We leverage our capabilities, resources and company experience in successfully managing to complete Engineering Drawings of Bofors Artillery gun which used for Modernization of Artillery gun (Dhanush). Our team is responsible for Digitization, modification and updation of 155mm/39 gun to 155mm and 45 calibre gun has a maximum effective range of 38 km in plains. We also Re-engineered complex casting parts of Bofors gun to continual improvement for ever-increasing customer value and sustainability.

Unmanned Aerial Vehicle and Missile